Why Smart South African Businesses Choose Odoo as their Inventory Management Software

In our South African economy, efficient inventory management isn’t a luxury — it’s a necessity to stay competitive. Whether you run a warehouse in Gauteng, distribute goods in Cape Town, or manage manufacturing in Durban, Odoo Inventory Management Software gives your business real-time visibility, automation, and control — all in one integrated system.

Why South African Businesses Are Switching to Odoo Inventory

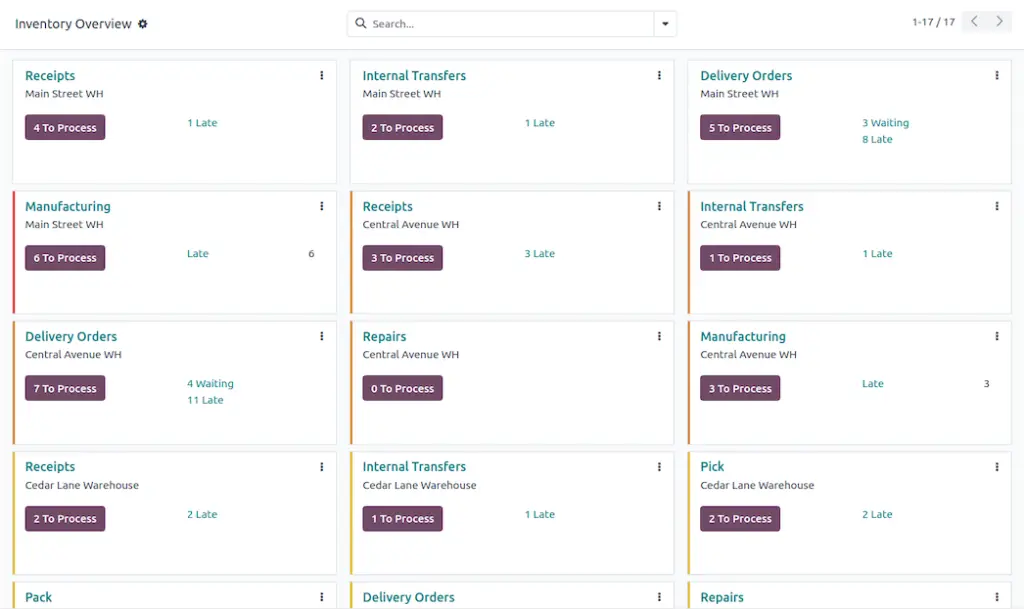

Real-Time Visibility Across All Branches and Warehouses

South African companies often operate across regions — Cape Town, Durban, Johannesburg, Gqeberha, and beyond. Odoo provides real-time inventory levels, helping you eliminate stock shortages, reduce delays, and maintain accurate stock counts across multiple branches.

XRA has solved many outstanding problems for its clients who have struggled to find a practical, easily integrable solution for their inventory management. See how we optimised Inventory Management for an Auto Parts dealer in Durban across their branches in Durban and Johannesburg using a customised Odoo Solution.

Automated Replenishment That Prevents Stock-outs

Load-shedding, supplier delays, and long lead times can disrupt inventory flow. Odoo lets businesses create automated reorder rules, minimum stock levels, and supplier lead times — ensuring stock replenishes before it runs out.

With Odoo, you have Real-Time Inventory Management.

Barcode and Mobile Scanning for Faster Operations

Odoo supports GS1, EAN13, EAN14, and custom barcodes — ideal for South African retail and wholesale environments. Teams can process receipts, pickings, stock takes, and transfers using barcode scanners or mobile devices.

Efficient Warehouse Routes and Picking Strategies

Odoo streamlines every warehouse workflow:

- Batch picking

- Wave picking

- Cluster picking

- FIFO/LIFO routing

- Put-away rules

This helps reduce labour time, speed up dispatch, and improve order accuracy — critical for improving customer satisfaction in South Africa’s competitive market.

Full Product Traceability for Compliance

Odoo allows a complete lot and serial tracking, which is essential for:

- Food and beverage suppliers

- Pharmaceuticals

- Manufacturing

- Importers and distributors

This traceability improves audit readiness and supports product recalls when required.

Key Benefits of Odoo Inventory for South African SMEs

Lower Operational Costs

By improving accuracy and automating manual tasks, businesses reduce wastage, stock shrinkage, and labour time.

Better Cash Flow Control

Avoid tying up money in excess stock — Odoo’s forecasting tools help you buy smarter.

Seamless Integration With Accounting, Sales & POS

Inventory movements automatically update accounting and sales, reducing manual capture and eliminating human error.

Rapid Onboarding and Staff Training

Odoo’s intuitive interface helps South African teams adopt digital processes quickly.

Scales With Your Business

Start with a single warehouse and expand to multiple branches, delivery points, and distribution hubs without migrating systems.

Frequently Asked Questions (FAQ)

Q1: Is Odoo Inventory suitable for South African small businesses?

Yes — Odoo is ideal for SMEs because it reduces manual processes, cuts costs, and improves efficiency.

Q2: Can Odoo manage more than one warehouse?

Absolutely. You can manage multiple branches or warehouses across South Africa from a single system.

Q3: Does Odoo support barcode scanning?

Yes. Odoo works with barcode scanners, mobile scanners, and GS1-compliant barcodes.

Q4: Does Odoo integrate with accounting and sales?

Yes — all modules work together seamlessly, including Odoo Accounting, Sales, Manufacturing, and POS.

Q5: Can Odoo help with stock shortages?

Yes. Automated reorder rules and forecasting tools dramatically reduce stock-outs.

Q6: Is Odoo cloud-based?

Yes — Odoo can be hosted in the cloud or on-premise, depending on your requirements.

Why Choose Odoo Inventory for Your South African Business

Odoo Inventory gives your business the tools to operate more efficiently, save money, and improve customer experience. Whether you're scaling an e-commerce store, running a manufacturing facility, or managing distribution across the country, Odoo provides the visibility and control you need to grow confidently.